Anatomy

IN-DEPTH LOOK AT A CIGAR .

A cigar’s anatomy is measured in detail and must meet a series of requirements during its production in order to be called a cigar.

Size

LENGTH, RING GAUGE AND DIAMETER

The size of a cigar is measured by two dimensions:

RING GAUGE

This is the diameter of the cigar.

It is officially measured in inches and is expressed in 64ths of an inch. One inch is equivalent to 25.4 millimetres.

LENGTH

This is measured from the cap, or head, of the cigar to the other end (foot).

The diameter of a cigar is determined by the filler. It is divided into 3 groups:

THICK

The trend in recent years has been towards thicker diameter ring gauges.

These are known as vitolas, and they have an excellent combustion and great draw.

They also usually have a milder flavour and highly balanced blend.

MEDIUM

Habanos with this diameter were the most classic in the vitolario until the trend towards thicker cigars began.

The longer these cigars are, the more demanding they become in terms of their draw, although they also allow for greater blend perception.

THIN

These cigars have diameters of between 10 and 16 millimetres and generally little tobacco weight. They usually offer short smokes that rarely exceed 25 or 30 minutes.

As they have a narrower ring gauge, they allow you to enjoy their blends and perceive all the nuances throughout the smoke.

Form

STRAIGHT AND IRREGULAR

The size of a cigar is measured by virtue of two dimensions.

STRAIGHT

This is the most common type of cigar, straight along its entire length and with parallel parts.

IRREGULAR

This type of cigar ends with a point at one end, although it is known as a doble figurado if it does so at both ends.

Vitola

DE SALIDA / GALERA

«Robustos»

VITOLA DE GALERA

The vitola de galera is defined by the length, gauge and shape of the cigar. It is the name used by the factories to designate each forma

“Serie D No 4”

VITOLA DE SALIDA

The vitola de salida is the commercial name given to a cigar, which may or may not coincide with the galera.

The same galera often has different salida cigar shapes depending on the brand.

VITOLA DE GALERA

SALIDA

Ring gauge 50

VITOLA DE GALERA

SALIDA

BEST-KNOWN VITOLAS

SMOKING TIME

30’

Perlas

40

102 mm

Petit Robusto

50

102 mm

SMOKING TIME

from 30’ to 45’

Marevas

42

129 mm

Coronas Gordas

46

143 mm

SMOKING TIME

from 45’ to 90’

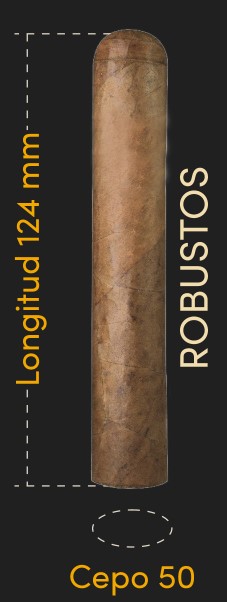

Robustos

50

124 mm

Cañonazo

52

150 mm

Pirámides

52

156 mm

SMOKING TIME

> 90´

Julieta No. 2

47

178 mm

Composition

PARTS OF A CIGAR

A premium cigar is made up of three components and these determine its personality:

WRAPPER

This is the very thin, flexible outer leaf that envelops the cigar. It has practically no influence on the final flavour of the cigar.

CAPOTE

This is the leaf that surrounds the filler and defines the shape of the cigar.

FILLER

This is the inner part, in which three types of leaf are normally combined: volado (providing combustibility), seco (providing aroma) and ligero (providing flavour).

STRUCTURE

A premium cigar has three main parts:

CAP

This is the head of the cigar,

the part we cut to start smoking.

BAND

This is the decorative band around the cigar that identifies the brand.

It arose to prevent important customers from staining their gloves when smoking. They were introduced by the European businessman Gustav Bock around 1860. If the band is removed, it is best that the cigar is hot and at least the first third of it has been consumed.

FOOT

This is the end that is lit

COLOURS

The colour of the cigar wrapper leaf depends on the position of the leaf on the tobacco plant and level of fermentation. Although there are many different shades, they can be divided into five types:

Claro

Colorado claro

Colorado

Colorado maduro

Maduro

Quality

QUALITY CONTROL

Technicians check that the weight, length, ring gauge, construction, wrapper appearance, cap assembly and consistency are appropriate. The cigars are then handed over to the tasting team and, once validated, they are left to rest for a week to eliminate excess humidity.

HIERARCHY

A complete hierarchy exists at the cigar quality control stage. Seasoned cigar roller supervisors check each group of rollers, observing their techniques and verifying their workmanship and dimensions. In turn, the work of the cigar rollers is closely supervised every day by the galera manager.

BUNDLES

In the case of Habanos, once the tobaccos have been finished, they are put together in bundles of 50 units, known as media ruedas, which are marked with the number of the cigar roller, type of cigar and date of production.

The bundles are transferred to the quality control department, where technicians check the cigars for weight, length, thickness, consistency, construction and external appearance, particularly examining the draw of the wrapper leaf and cap assembly. Random checks are also performed on some of the finished cigars, unravelling them to check internal construction and blend.

DRAW MACHINE

The latest technique for quality control, introduced in 2001, was a machine to test the draw of cigars before the wrapper is applied to each unit. Subsequent further quality controls are carried out by the sorter and inspector before the cigars are packed in boxes. Finally, all packs not displaying the required appearance are withdrawn from production.

Band

PLACING THE BAND

The cigars are sorted by colour and tone and placed in a box in order from darkest (left) to lightest (right). An anillador, or bander, then carefully places a band on each cigar and puts it back inside the box.

SHADE

Have you ever noticed that all cigars in a box have the same shade? The colour of a wrapper leaf of our cigars is completely natural, with no artificial process used to force it. The leaves of the upper levels of the plant are naturally darker and become darker still during the fermentation process.

SELECTION

The sorters, among the most experienced workers in the factories, select the raw cigars, dividing them by colour in a pattern of columns and rows with more than 60 different shades. They then select the cigars by colour to fill a box, arranging them from darkest to lightest from left to right across the box if there is any slight difference

BANDS

Cigar bands were introduced around 1860 by Gustavo Bock, a European who had come to Havana to make his fortune in cigars. According to legend, his idea arose with the intention to prevent his most refined customers from staining their white gloves when smoking.

Whether this is true or not, cigar bands became one of the most formidable and popular symbols of Habanos, highly prized by collectors and often imitated by competitors.